MAIN BUSINESS

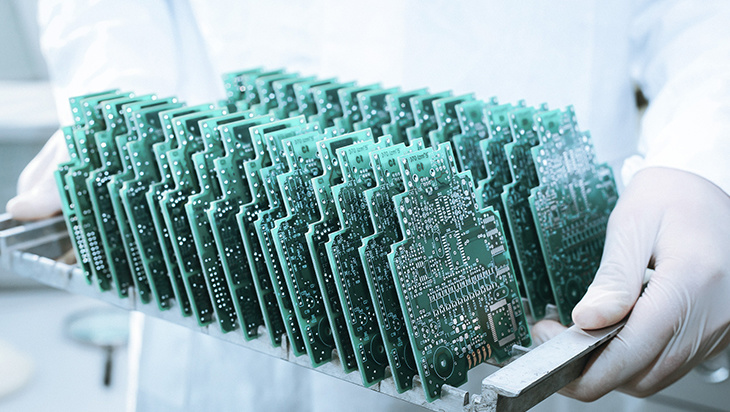

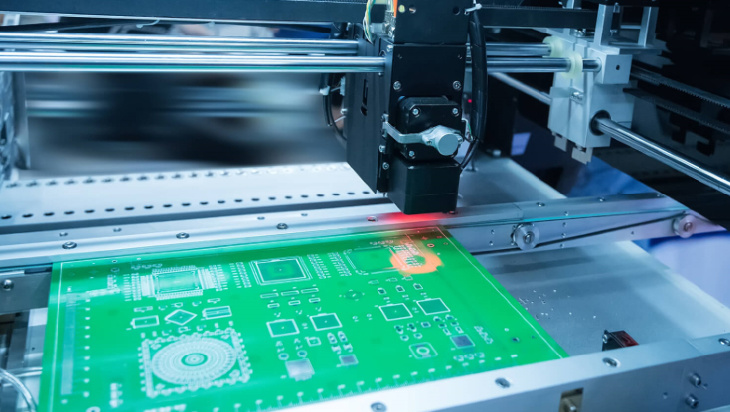

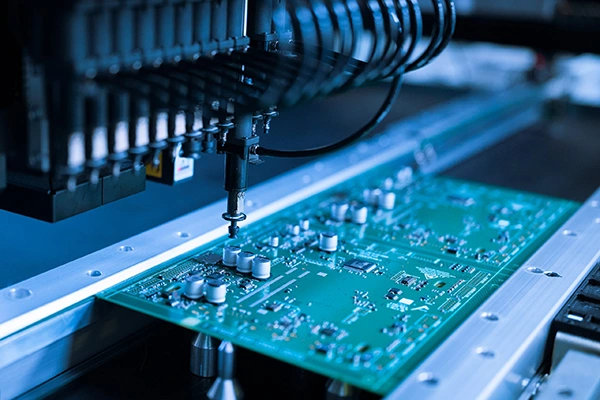

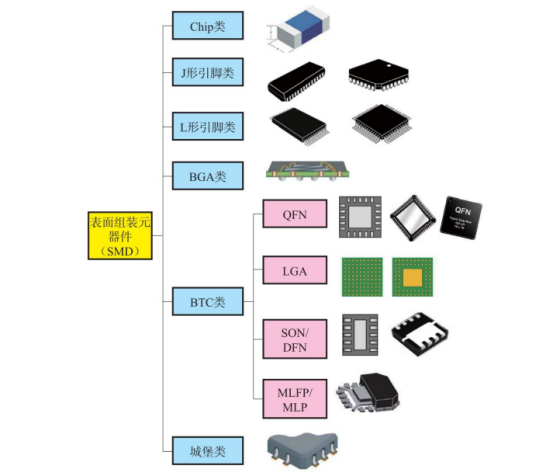

The company has a complete process from SMT patch to DIP welding and crimping. SMT has newly imported Samsung high-speed taping machine, full-automatic printing machine, reflow soldering, AOI, SPI optical on-line testing equipment; As well as dispensing machine, X-Ray machine and BGA welding machine. SMT monthly post loading capacity of up to 26.2 million points. DIP has an assembly line from plug-in, wave crest welding, post-welding and single board testing, with a daily processing capacity of 1000PCS.

Strong PCB design ability and short cycle. It involves communication, network, medical, financial, security, industrial control, household appliances and intelligent consumer products.

We can provide various types of PCB production, and can meet customer sample, small and medium-sized batch of PCB rapid manufacturing services.

The company has rich practical experience in component procurement and high-quality supplier procurement channels, and can quickly complete the procurement task of components in small and medium batches. We have a sound supplier management system and evaluation system to select high-quality suppliers, ensure the quality of incoming materials and delivery time of suppliers, and ensure high quality and low price. In terms of material storage, we have a standardized storage site of 500 square meters, and use ERP system for material inventory management. Common components, such as capacitors and resistors, are stored in stock, and general materials are available in one station.

Structural Processing and Design

It provides CNC processing and hardware stamping services, and its business involves precision equipment, hardware structural parts, tool testing and inspection tools and other mechanical parts processing services. At the same time, it can also provide you with structural design services of standard communication equipment and industrial control host

The assembly manufacturing adopts the mode of prototype independent workstation and small and medium batch assembly line, with the manufacturing capacity of 600 sets per day (taking the industrial switch as an example); It has a complete process of manufacturing, testing, aging, and high and low temperature environment experiments.

ABOUT US

Founded in September 2008, Shenzhen Qingjian Electronic Technology Co., Ltd. is located in Apollo Future Industrial Park, Yuanshan Street, Longgang District, Shenzhen. It has more than 2600 square meters of production workshops and a complete electronic manufacturing supply chain from procurement, warehousing, PCBA processing, assembly manufacturing, testing and aging. The production process has advanced automatic production equipment and complete process detection equipment. The ERP system is used to integrate and manage the supply chain resources, and the MES system is used to manage the whole production process. Provide customers with fast and high-quality one-stop electronic manufacturing supply chain services for R&D samples and small and medium batch products. For many years, our customers have been distributed in military manufacturing, scientific research institutes and enterprises, mainly involving communication, network, medical, finance, security, industrial control, household appliances, intelligent consumer products, etc.

Focus on providing "one-stop" electronic manufacturing supply chain services focusing on procurement, PCBA manufacturing, and machine manufacturing and testing.

Learn more >年

Incorporated In

+

M²

Plant Area

项

+

Qualification

家

+

Hundreds

Serving Customers

TECHNOLOGY

NEWS

31

2022-10

31

2022-10

22

2021-09

02

2021-06

PARTNERS