COMPANY PROFILE

Shenzhen Qingjian Electronic Technology Co., Ltd

Shenzhen Qingjian Electronic Technology Co., Ltd. (referred to as "Qingjian Electronics") is a wholly-owned subsidiary of Bangyan Technology Co., Ltd. It was established in September 2008 and is located in Apollo Future Industrial Park, Yuanshan Street, Longgang District, Shenzhen. It has a modern production base covering an area of over 2260 square meters. We have professional technology, advanced equipment, strict management, and high-quality services, committed to providing customers with a "one-stop" electronic manufacturing supply chain service from PCBA design, board making, procurement, PCBA manufacturing to complete machine manufacturing.

Professional strength, forging excellence We focus on accurately transforming every idea and concept into high-quality electronic products. We have rich successful experience in both sample trial production and small to medium batch processing and OEM production. We not only have a high level of customer cooperation and service awareness, but also are committed to providing professional and rational suggestions during the production process to help customers improve the shortcomings in their products. Our process production line covers a comprehensive range from SMT and DIP to assembly, aging, testing, and packaging, striving for perfection in every aspect.

Empowered by technology, precise and efficient Advanced technology is the cornerstone of quality. Qingjian Electronics is equipped with industry-leading EMS hardware facilities, including production equipment such as fully automatic tin printing machines (GKG), Samsung high-speed multifunctional surface mount machines (S1, S2), German ERSA reflow soldering/wave soldering, etc. Testing equipment includes Omron 2D/3D-AOI, Omron 3D-RAY Koyang SPI, Blue Eye first piece inspection instrument, etc. These top-notch devices can not only easily handle the placement of small components such as 0201 and 01005, but also accurately handle complex chips such as 0.3mm ultra-high precision QFP and 0.3mm ultra-high precision BGA, ensuring that every detail is achieved to the extreme.

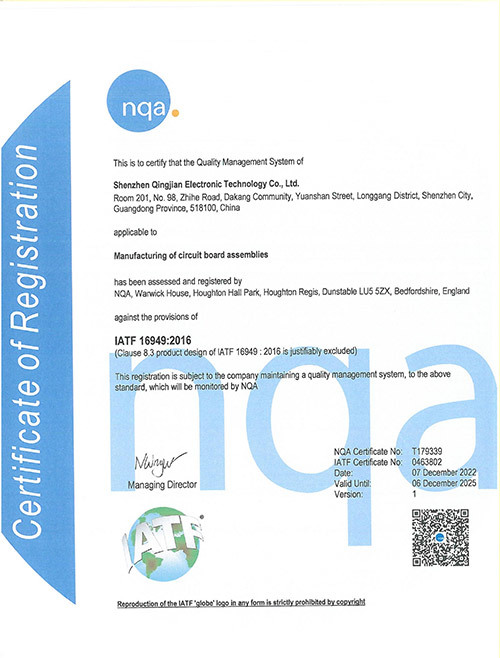

Strict management, customer first At Qingjian Electronics, we strictly adhere to the ISO9001 quality management system and have established a comprehensive process, quality, and logistics management system. Our management team is based on the core concept of "customer-centric, product quality fundamental". Whether it is fast SMT placement for engineering research and development samples or bulk product delivery, we can flexibly arrange and meet customer needs. We promise that every order will be delivered on time, with quality and quantity, and customer satisfaction is our highest pursuit.

Wide range of services, win-win co creation Qingjian Electronics' services cover a wide range of fields, including military manufacturing, research institutes, communication industry, network industry, medical industry, finance industry, security industry, industrial control industry, audio and video industry, automotive electronics, as well as multiple segmented markets such as household appliances, smart consumer products, and small and medium-sized enterprises. We rely on our rich manufacturing experience and professional technical strength to provide customers with professional, efficient, and thoughtful solutions, helping them stand out in the fierce market competition.

DEVELOPMENT PATH

ADVANTAGE

Always pay attention to customers' needs

Customer first and meeting customers' needs are the premise of Yibo's survival. All requirements of customers can be met by establishing a set of customer service centered management system, increasing investment in technology development, and improving staff quality through internal construction.

Brand strength guarantee

Qingjian Electronics has 8 imported SMT mounters, 4 high-speed machines, 4 medium speed machines, plug-in lines, post welding lines, testing, assembly line processing equipped with full-automatic loading machine, printing machine and full plate receiving machine, automatic product inspection AOI detection equipment, which can efficiently process SMT mounters and eliminate the hidden trouble of processing quality of your products.

Rigorous test of real materials

PCBA proofing never uses fake auxiliary materials to ensure that every product produced meets the customer and market demand. Stable suppliers guarantee our production demand and meet the customer's PCBA processing and production requirements. Each product has passed strict inspection and testing by QC, AOI, FCT, etc.

Rich experience in assembly and processing of electronic products

Serve many electronic enterprises, electronic product processing plants, and export to Europe and other countries. The quality is confirmed, the delivery time is stable, the incoming materials are complete and can be delivered within 3-5 days, and the next day can be delivered in case of urgent demand.

Rigorous quality assurance system

After years of experience, Qingjian Electronics has created a set of evaluation specifications for different products.

Service awareness

We are willing to grow and grow together with you.

QUALIFICTION