What is SMT surface mount?

2022-10-08 15:09

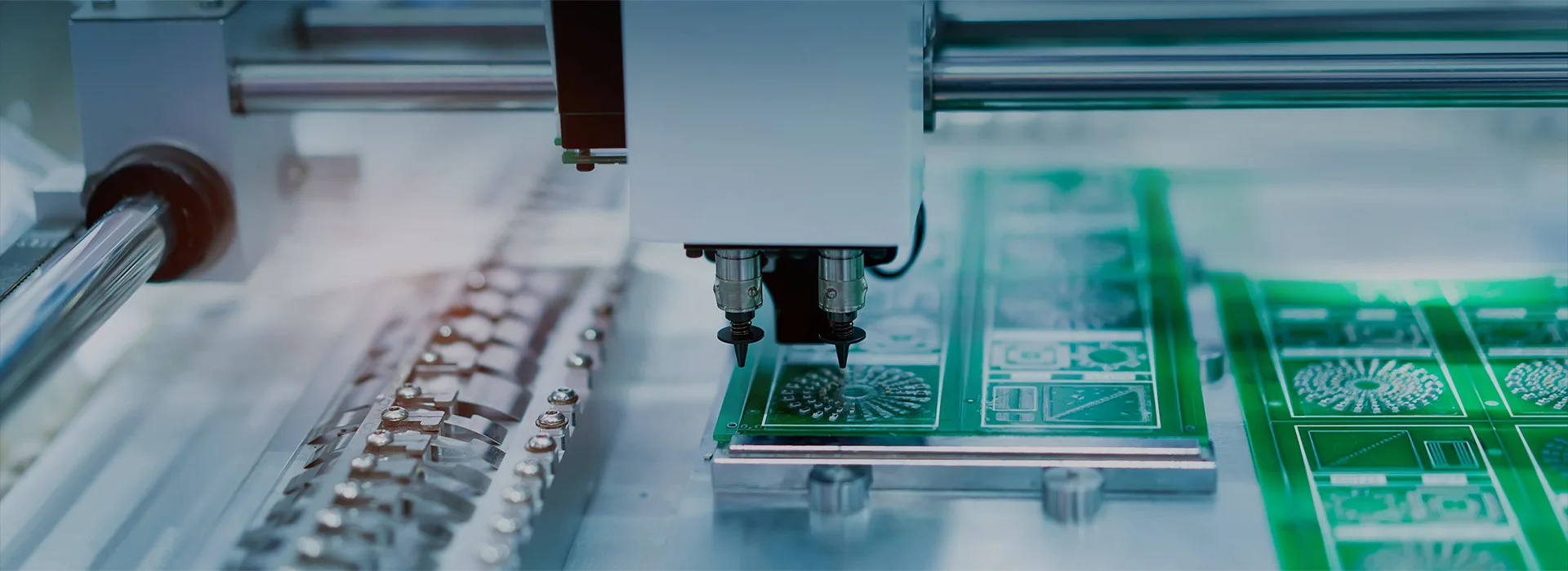

SMT, the full name is surface mount technology. SMT patch is a method to install components or parts on the board. Due to better results and higher efficiency, SMT has become the main method used in PCB assembly.

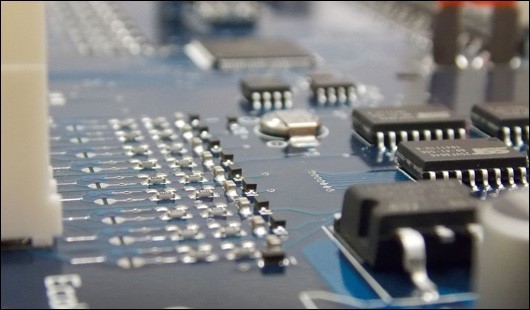

In the past, PCB manufacturers mainly used through hole assembly to install components. But SMT uses welding technology to replace the previous assembly method. And you can find PCBs manufactured by SMT assembly program in all electronic industries, such as computers, telecommunications, smart phones, household appliances, etc. The general process of SMT assembly includes printing solder paste, installing components, reflow soldering, AOI or AXI

Advantages of SMT assembly

·Small size and light weight

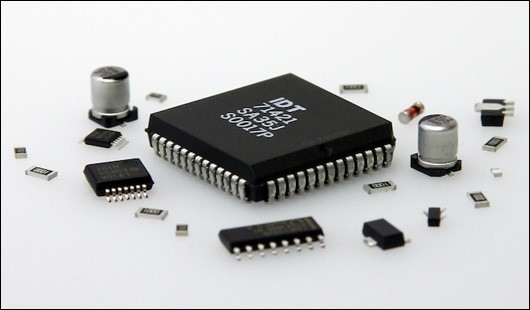

Using SMT technology to directly assemble components on the board helps reduce the overall size and weight of PCB. This assembly method allows us to place more components in a limited space, thus achieving a compact design and better performance.

·High reliability

After prototype confirmation, the entire SMT assembly process is almost completed automatically by precision machines, thus minimizing the errors that may be caused by manual work. Due to automation, SMT technology ensures PCB reliability and consistency.

·Cost savings

SMT assembly is usually achieved by automatic machines. Although the input cost of machines is high, automated machines can help reduce the manual steps in the SMT process, which can significantly improve productivity and reduce labor costs in the long run. And the materials used are less than through hole assembly, and the cost will be reduced.

SMT assembly capability of Qingjian Electronics

Jingbang has a fully computerized SMT workshop, which can be used for mass production. For small batch orders, prototype manufacturing or complex parts, we also provide manual welding services. We have several pcb types for assembly: FR4 board, aluminum board, flexible board, rigid flexible combination board. In addition to SMT assembly, other assembly types such as BGA assembly, through-hole assembly, hybrid assembly and kit assembly are also available. When you place an SMT order, you should provide ese files: Gerber files (for PCB manufacturing), BOM (bill of materials) lists, CPL (component placement list) files, or PNP (pick and place) files.

Qingjian Electronics has a professional team to provide turn key services for SMT orders. Our engineers focus on every step of PCB manufacturing and PCB SMT prototype. Whether you provide components or we provide components, all components and SMT processes are carefully checked and matched according to your design and requirements.

Related Articles

2022-10-10

2022-11-03